Early in my IT career I was asked to evaluate a sister division struggling with an ERP implementation. The evaluation revealed that senior division management did not want to change any of their existing business processes. As a result, the IT team was struggling to modify the ERP system to fit the existing way of working. This was adding to the project costs and timeline. More importantly the business was missing a once in a decade opportunity to optimize its processes, and positively improve its competitive position.

Implementing new technology without changing the underlying business processes results in excessive amounts of customization. This adds to the project costs and makes the system more difficult and expensive to support. Since work is being done in the same way productivity improvements are minimal at best, and often deteriorate at least for a time as people adapt to the new system interfaces.

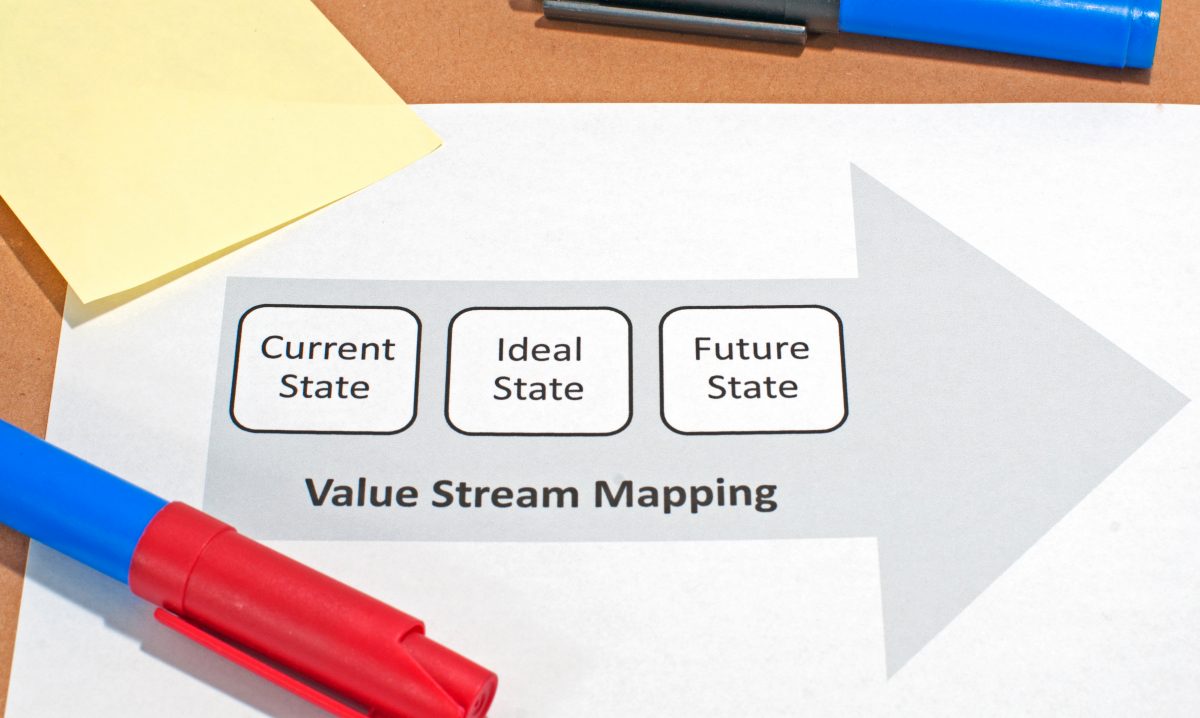

Major IT enabled initiatives should only be undertaken when an organization is committed to transforming the way work gets done. The team should be staffed with process experts who understand lean concepts. These process experts should start by observing the existing processes to identify waste. Then working with people who understand the technology they should design “to be” processes that eliminate as much waste as possible without overly customizing the system.

As an example, we reviewed the goods receiving process in one of our plants. We observed deliveries showing up unexpectedly, goods being relabeled, goods being moved multiple times before they were put away, people waiting for labels to print, and data being reentered from shipping documents into the receiving system. As part of our new solution we instituted a mandatory Advanced Ship Notice (ASN) for all deliveries, and a delivery appointment process that ensured deliveries were made in a know time window. By integrating the ASN with our receiving system we eliminated duplicate data entry. This also allowed us to have all the proper labels printed automatically prior to goods arrival, which reduced wait time and the number of goods movements. The receiving team embraced the new process because it eliminated work by simplifying their jobs, and productivity improved by over 20%. While some of the improvements were enabled by the new system, the most significant improvements were driven by process changes that were independent of the technology. My simple advice to you is that new technologies with old processes leads to a deterioration in your results, while new technologies plus optimized business processes results in a step change improvement in your competitive position. Make sure you invest in the process expertise you need to fall into the winning group.